Coatings, Free Full-Text

By A Mystery Man Writer

Last updated 20 Sept 2024

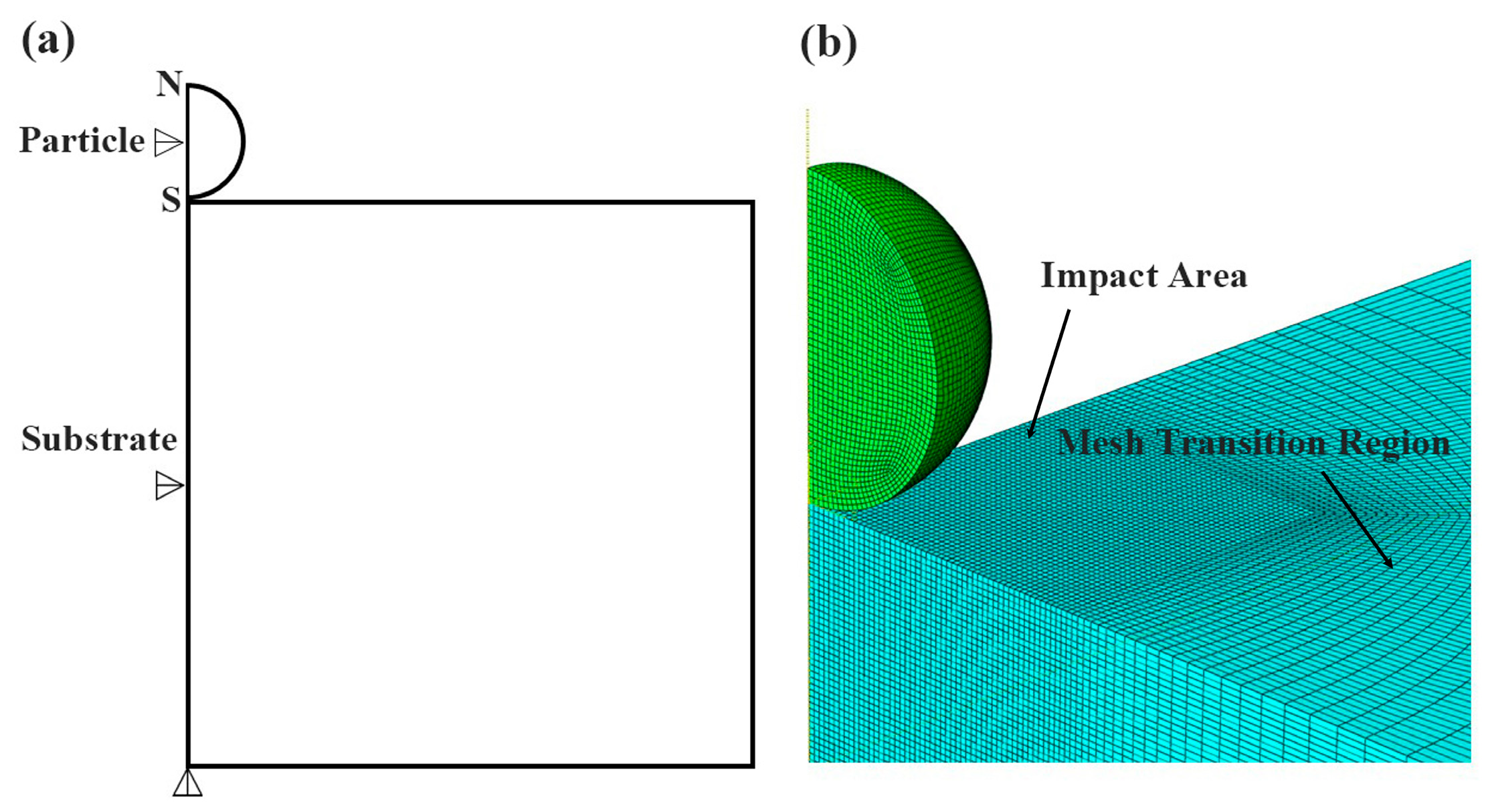

NiCoCrAlY coatings are commonly used as bond-coat in thermal barrier coatings due to their excellent high-temperature oxidation resistance and suitable thermal expansion coefficient between the superalloy substrate and ceramic top layer. Previous studies have shown that the NiCoCrAlY coatings prepared by cold spray (CS) exhibit excellent comprehensive properties. In the process of cold spray, the solid particles impact onto the substrate with a high velocity, powder particles and the substrate undergo plastic deformation, and the coating is deposited finally. When the velocity of the impacted particles reaches a certain value (critical velocity), the particles can be effectively deposited on the substrate. Due to the short impact time and large plastic deformation of the cold spray process, the process is difficult to be observed in the actual experiment process in real time. Therefore, the current work has used the explicit dynamics method in finite element numerical simulation to simulate the deposition behavior of the particle during the cold spray process. By changing the impact velocities and sizes of particles, the changes in temperature (TEMP), equivalent plastic strain (PEEQ), deformation characteristics of the particle and substrate after particles being completely deposited on the substrate have been obtained. The critical velocity of particle deposition is about 600 m/s, and the larger the particle, the easier it is to deposit. And the current modeling and simulation work provided the theory instruction for the preparation of NiCoCrAlY coatings with excellent performance via cold spray.

PDF) Effect of methyl methacrylate content on coatings' properties of palm oleic acid-based macromer

Coatings, Free Full-Text

TEC Coatings

Coatings Free Full-Text Resistance Of PVD Coatings To, 56% OFF

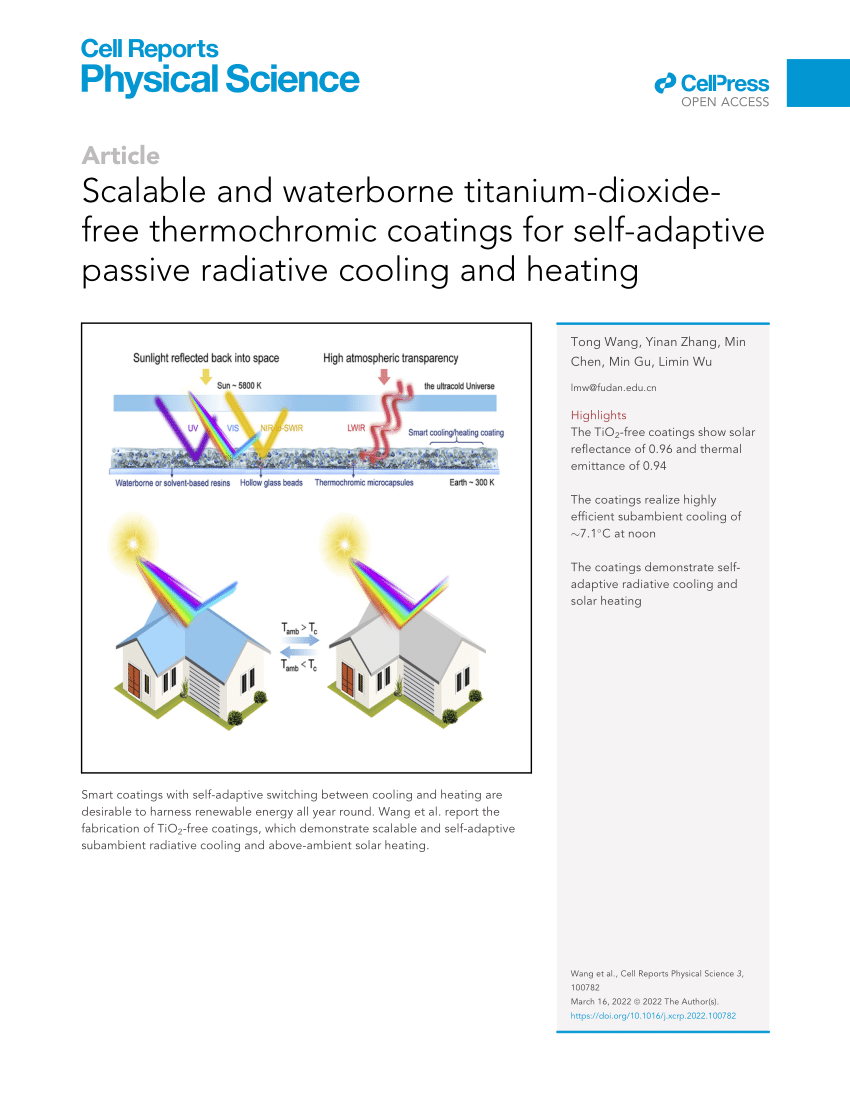

PDF) Scalable and waterborne titanium-dioxide-free thermochromic coatings for self-adaptive passive radiative cooling and heating

20 LITRE INDUSTRIAL FLOOR PAINT - HEAVY DUTY - ALL COLOURS - QUICK FREE DELIVERY

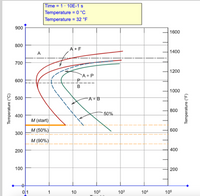

Solved b) Rapidly cool to 625°C, hold for 1 s, then quench, c hold

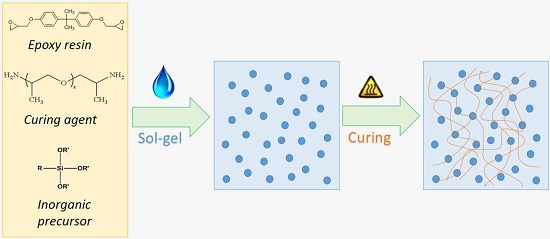

Thermoset Cure Chemistry Part 3: Epoxy Curing Agents - Polymer

Surface & Coatings Technology 1992: Vol 52 Index : Free Download, Borrow, and Streaming : Internet Archive

Recommended for you

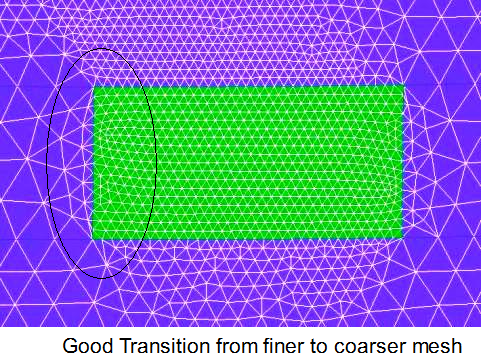

Examples of mesh transition.14 Jul 2023

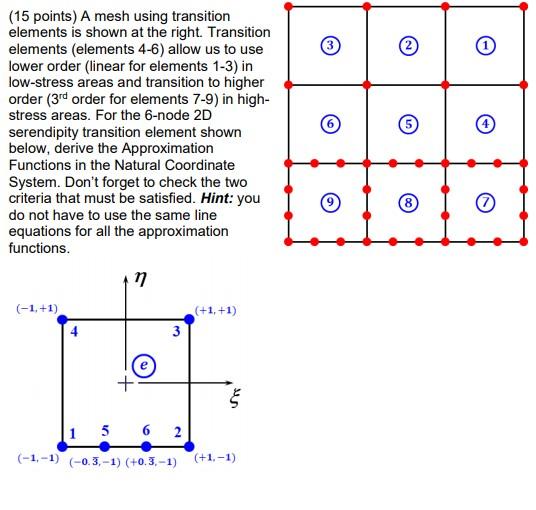

Examples of mesh transition.14 Jul 2023- Solved (15 points) A mesh using transition elements is shown14 Jul 2023

- Mesh Transition in FEMAP14 Jul 2023

ICEM CFD: Tips and Tricks to Generate Mesh for CFD Simulations14 Jul 2023

ICEM CFD: Tips and Tricks to Generate Mesh for CFD Simulations14 Jul 2023 Halftone seamless pattern mesh texture transition Vector Image14 Jul 2023

Halftone seamless pattern mesh texture transition Vector Image14 Jul 2023 Automated 3D Mesh Transition or Mesh Refinement in HyperMesh, Part14 Jul 2023

Automated 3D Mesh Transition or Mesh Refinement in HyperMesh, Part14 Jul 2023 Experimental and numerical studies of nonlinear ultrasonic14 Jul 2023

Experimental and numerical studies of nonlinear ultrasonic14 Jul 2023 Recombination of Voxel Transition Cells for OpenFOAM Meshes14 Jul 2023

Recombination of Voxel Transition Cells for OpenFOAM Meshes14 Jul 2023 Capezio Professional Mesh Transition Tight with Back Seams14 Jul 2023

Capezio Professional Mesh Transition Tight with Back Seams14 Jul 2023 Highlight normal transition edges in STL file - MATLAB14 Jul 2023

Highlight normal transition edges in STL file - MATLAB14 Jul 2023

You may also like

Drawer Organizer Divider Underwear Organizer, 24 Cell Collapsible Closet Cabinet Organizer Underwear Storage Boxes for Storing Socks, Bra, Handkerchiefs, Ties, Belts14 Jul 2023

Drawer Organizer Divider Underwear Organizer, 24 Cell Collapsible Closet Cabinet Organizer Underwear Storage Boxes for Storing Socks, Bra, Handkerchiefs, Ties, Belts14 Jul 2023 Pack de 3 Boxers de Malha · Polo Ralph Lauren · El Corte Inglés14 Jul 2023

Pack de 3 Boxers de Malha · Polo Ralph Lauren · El Corte Inglés14 Jul 2023 FOR LOVE & LEMONS | S/M | Plum Purple Double Strap Ribbed Sports Bra MSRP$9014 Jul 2023

FOR LOVE & LEMONS | S/M | Plum Purple Double Strap Ribbed Sports Bra MSRP$9014 Jul 2023 Sexy Women's See through Bra Bustier Bralette Crop Top Underwear Wire-free Bras14 Jul 2023

Sexy Women's See through Bra Bustier Bralette Crop Top Underwear Wire-free Bras14 Jul 2023 Soma Yummie Short-Sleeve Shaping Bodysuit White14 Jul 2023

Soma Yummie Short-Sleeve Shaping Bodysuit White14 Jul 2023 White Silk Pink Lace Ruffled Panties Handmade, Silk Knickers, Women Sleepwear, Silk Sleepwear - Canada14 Jul 2023

White Silk Pink Lace Ruffled Panties Handmade, Silk Knickers, Women Sleepwear, Silk Sleepwear - Canada14 Jul 2023 Cabeau Evolution Classic Memory Foam Neck Pillow14 Jul 2023

Cabeau Evolution Classic Memory Foam Neck Pillow14 Jul 2023 Clamping Squares for Woodworking, 90 Degree Corner Clamp14 Jul 2023

Clamping Squares for Woodworking, 90 Degree Corner Clamp14 Jul 2023 Beautiful curvy, overweight girl Stock Vector by ©mazeina 16063937614 Jul 2023

Beautiful curvy, overweight girl Stock Vector by ©mazeina 16063937614 Jul 2023 Lucky Brand, Tops, Super Soft Sand Wash Wrap Top By Lucky Brand Small14 Jul 2023

Lucky Brand, Tops, Super Soft Sand Wash Wrap Top By Lucky Brand Small14 Jul 2023