Cold Metal Transfer Welding Technique

By A Mystery Man Writer

Last updated 20 Sept 2024

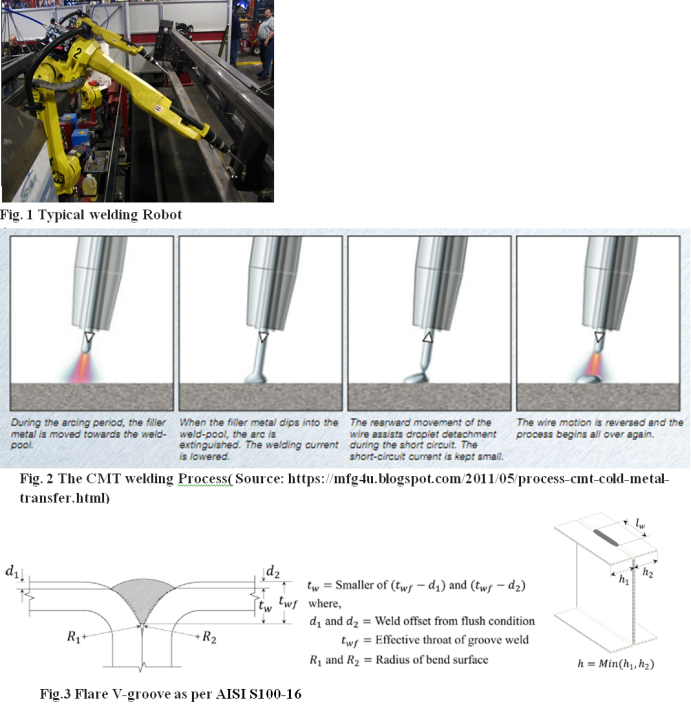

INTRODUCTION The cold metal transfer (CMT) welding technique is a modified MIG welding method that uses a pulsed arc to transfer metal from the welding wire electrode to the workpiece. The pulsed arc is created by a special power source that controls the current flow to the wire electrode.

Why We Use Cold Metal Transfer (CMT) Welding

PDF) Mechanical and microstructural properties of robotic Cold Metal Transfer (CMT) welded 5083-H111 and 6082-T651 aluminum alloys

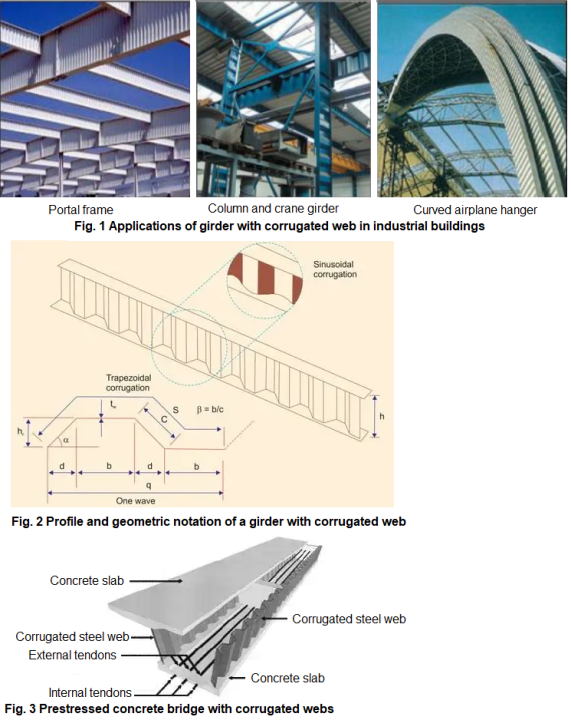

Plate Girders with Corrugated Webs

Effect of Welding Parameters on Mechanical Properties of Cold Metal Transfer Welded Thin AISI 304 Stainless-Steel Sheets

Precast, Prestressed Concrete Pile to Cast-in-Place Pile Cap Connections

Robotic welding power source upgraded with cold metal transfer process

PDF) CMT: Cold Metal Transfer

Metals, Free Full-Text

PDF) Mechanical Properties of Cold Metal Transfer (CMT) Welded 202 and 304 Stainless Steels

Is Our Consumption of Materials Sustainable?

Why We Use Cold Metal Transfer (CMT) Welding

Structural performance of cold metal transfer welding technique on cold-formed steel flare v-groove welds - ScienceDirect

Cold Metal Transfer Welding Technique

PDF] Mechanical and microstructural properties of robotic Cold Metal Transfer (CMT) welded 5083-H111 and 6082-T651 aluminum alloys

Recommended for you

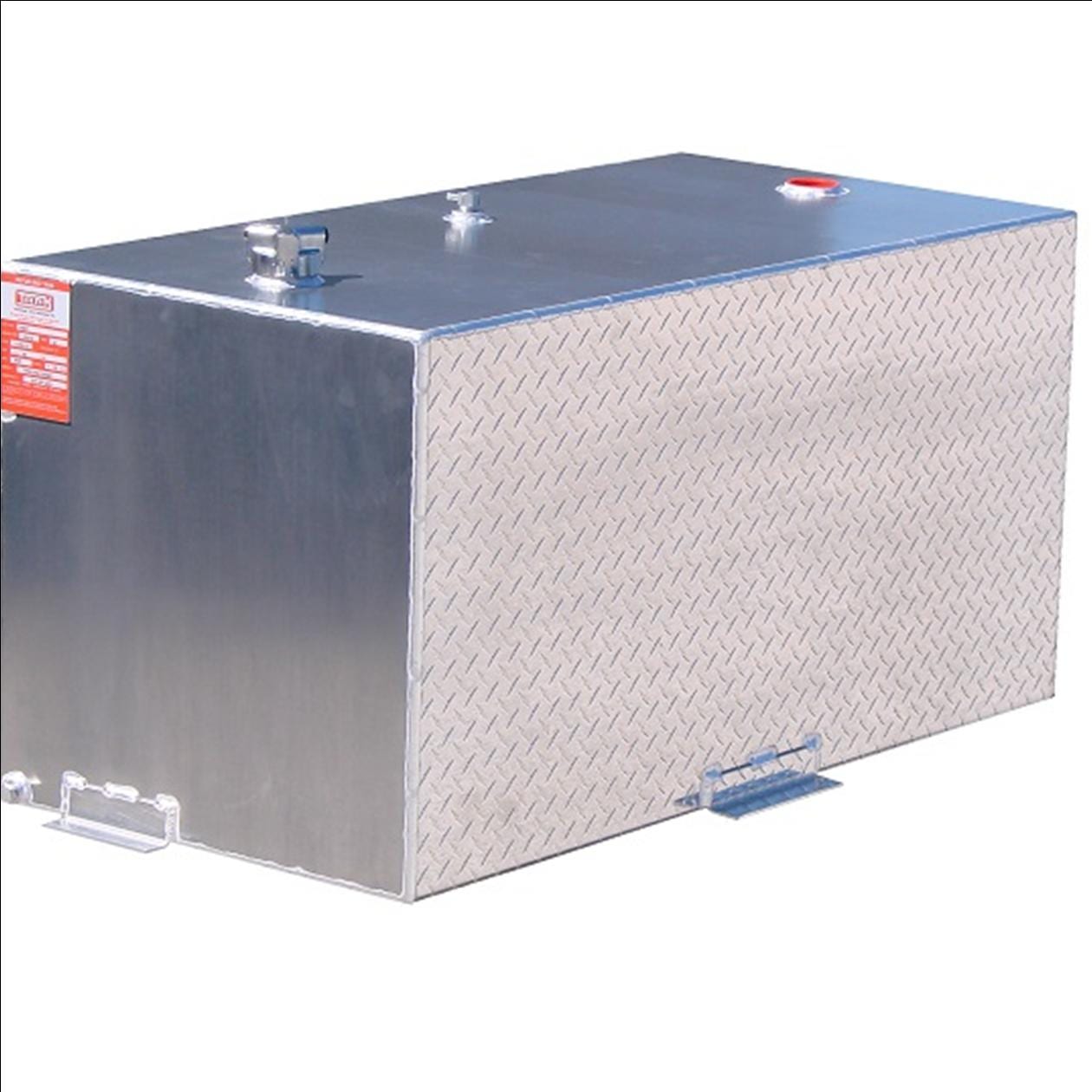

RDS 71787 Aluminum Transfer Fuel Tank Toolbox Combo 60 Gallon; Diamond Plate14 Jul 2023

RDS 71787 Aluminum Transfer Fuel Tank Toolbox Combo 60 Gallon; Diamond Plate14 Jul 2023 U.S.A. Made - PEX GUY Aluminum 4 ft U-Channel Heat Transfer Plates for 1/2 PEX - Radiant Heating (100pc/box) - Pex Tubbing14 Jul 2023

U.S.A. Made - PEX GUY Aluminum 4 ft U-Channel Heat Transfer Plates for 1/2 PEX - Radiant Heating (100pc/box) - Pex Tubbing14 Jul 2023 Synthware™ aluminum heat transfer block for round bottom flasks14 Jul 2023

Synthware™ aluminum heat transfer block for round bottom flasks14 Jul 2023- Dee Zee 111 gal. Brite-Tread Aluminum L-Shaped Transfer Tank with Chest Box, Black at Tractor Supply Co.14 Jul 2023

ATI Tank Severe Series 110 Gallon Rectangular Refueling Transfer Tank14 Jul 2023

ATI Tank Severe Series 110 Gallon Rectangular Refueling Transfer Tank14 Jul 2023 Acoustic Transfer Finish Aluminum Honeycomb Panel for Shopping Mall - China Honeycomb, Honeycomb Panel14 Jul 2023

Acoustic Transfer Finish Aluminum Honeycomb Panel for Shopping Mall - China Honeycomb, Honeycomb Panel14 Jul 2023 wood grain transfer 6063 aluminium profile for kitchen cabinet14 Jul 2023

wood grain transfer 6063 aluminium profile for kitchen cabinet14 Jul 2023 Excel Basic Aluminum Transport Chair with 12 Rear Wheels14 Jul 2023

Excel Basic Aluminum Transport Chair with 12 Rear Wheels14 Jul 2023 Expedition Aluminum Transport Chair by Drive Medical - Loop Locks and 12 Rear Flat Free Wheels14 Jul 2023

Expedition Aluminum Transport Chair by Drive Medical - Loop Locks and 12 Rear Flat Free Wheels14 Jul 2023 RDS Manufacturing 95 Gallon Aluminum Rectangular DOT Certified Transfer Tank14 Jul 2023

RDS Manufacturing 95 Gallon Aluminum Rectangular DOT Certified Transfer Tank14 Jul 2023

You may also like

Vintage Bad Brains You Gonna Get Yours Tour T-Shirt14 Jul 2023

Vintage Bad Brains You Gonna Get Yours Tour T-Shirt14 Jul 2023 PGM Fit Long Plaid Golf Pants Men Elastic Comfortable Trousers Windproof Pants14 Jul 2023

PGM Fit Long Plaid Golf Pants Men Elastic Comfortable Trousers Windproof Pants14 Jul 2023 Prefeitura de SP cerca Praça da Sé com grades em meio a aumento de casos de violência14 Jul 2023

Prefeitura de SP cerca Praça da Sé com grades em meio a aumento de casos de violência14 Jul 2023 Safeguarding Mammography Equipment Beyond the Disinfectant Spray14 Jul 2023

Safeguarding Mammography Equipment Beyond the Disinfectant Spray14 Jul 2023 loose cropped tank tops|TikTok Search14 Jul 2023

loose cropped tank tops|TikTok Search14 Jul 2023 Accolade Hoodie - White14 Jul 2023

Accolade Hoodie - White14 Jul 2023 Women Chiffon Shirt Lady Casual Long Sleeve Girl Blouse Top Before Short Back Long Irregular Women Clothing Tops14 Jul 2023

Women Chiffon Shirt Lady Casual Long Sleeve Girl Blouse Top Before Short Back Long Irregular Women Clothing Tops14 Jul 2023 Alexia Leather Choker14 Jul 2023

Alexia Leather Choker14 Jul 2023 Fila Velour Leggings14 Jul 2023

Fila Velour Leggings14 Jul 2023 Hong Kong: Beijing Dismantles a Free Society14 Jul 2023

Hong Kong: Beijing Dismantles a Free Society14 Jul 2023